Come See Cornell Pump At ConExpo, on the shows opening Day. We’re in booth # B91323 through Saturday.

Come See Cornell Pump At ConExpo, on the shows opening Day. We’re in booth # B91323 through Saturday.

Learn about Cornell Co-Pilot , see our expanded SM pump line, and enter to win DJI mavic mini drone and more.

Where Every Golden Fry Meets Cornell engineering.

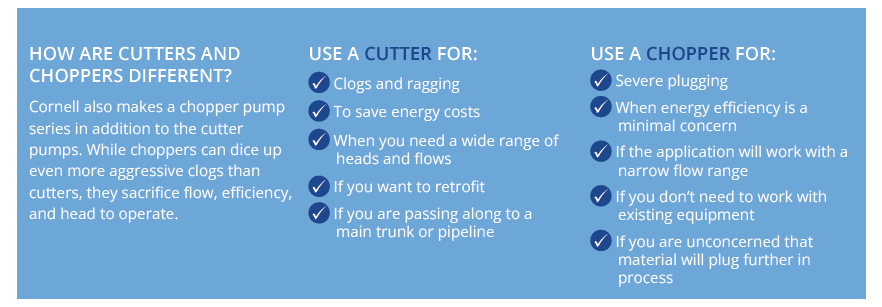

As wastewater compositions evolve—with flushable wipes, fibrous materials, and grease-laden solids now common—traditional non-clog pumps are increasingly unable to cope. Municipalities and industrial users face a critical choice: should they specify a cutter or chopper impeller for their toughest pumping applications?

In the world of mining, few factors impact equipment performance and lifespan more than wear and corrosion. Pumps, in particular, face a relentless barrage of abrasive slurries and chemically aggressive fluids that can prematurely degrade internal components. That’s why metallurgy isn’t just a minor detail; it’s a decisive factor in mining pump system reliability and cost of ownership.