Oil & Gas Pumps

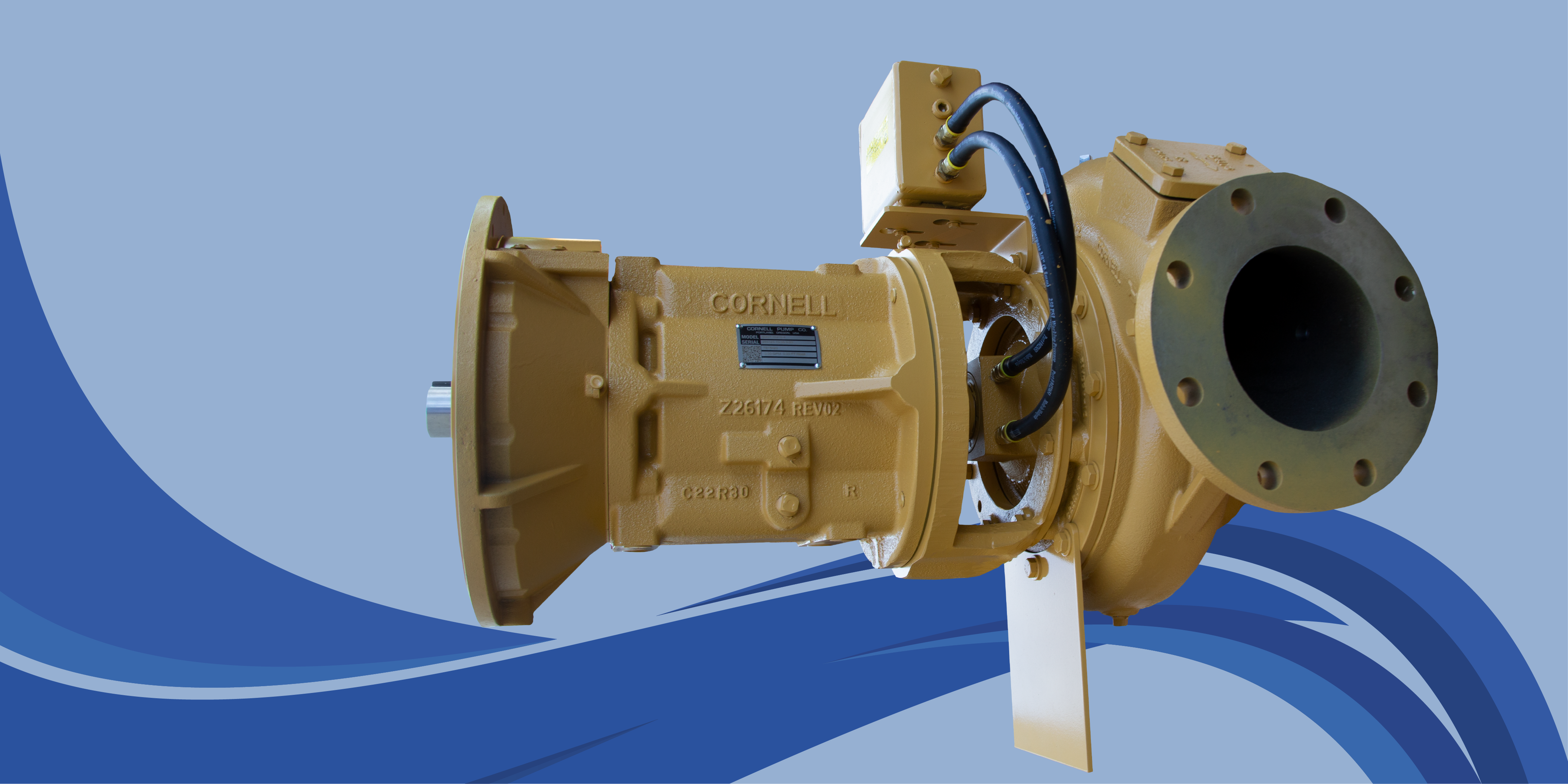

Cornell pumps have a reputation for being durable and reliable in harsh conditions. Since 1946, our pumps have been designed and manufactured to meet rigorous standards in Portland, OR. Cornell pumps are widely used in the oil and gas industry, hydraulic fracturing, due to their exceptional uptime, dependability, and efficiency.

On Cornell pumps for Oil & Gas applications, look for the distinctive appearance of the angular, muscular frame to know it’s a high-quality Cornell pump.

N-Series Solids Handling Pumps

Cornell's N-series pumps can handle rigid solids handling applications and are available in a range of discharge sizes from 1.25″ to 30″. There's a solution for your needs with different mounting configurations, including close-coupled, SAE engine-mount, horizontal frame-mount, vertical, and vertically coupled. The enclosed impeller design (for 2" to 10" solids and flows up to 40,000GPM) can handle complex materials, and a delta impeller is available for stringy materials, rags, and more. With over 30 years of reliable service in the wastewater industry, the N-series is a trusted choice.

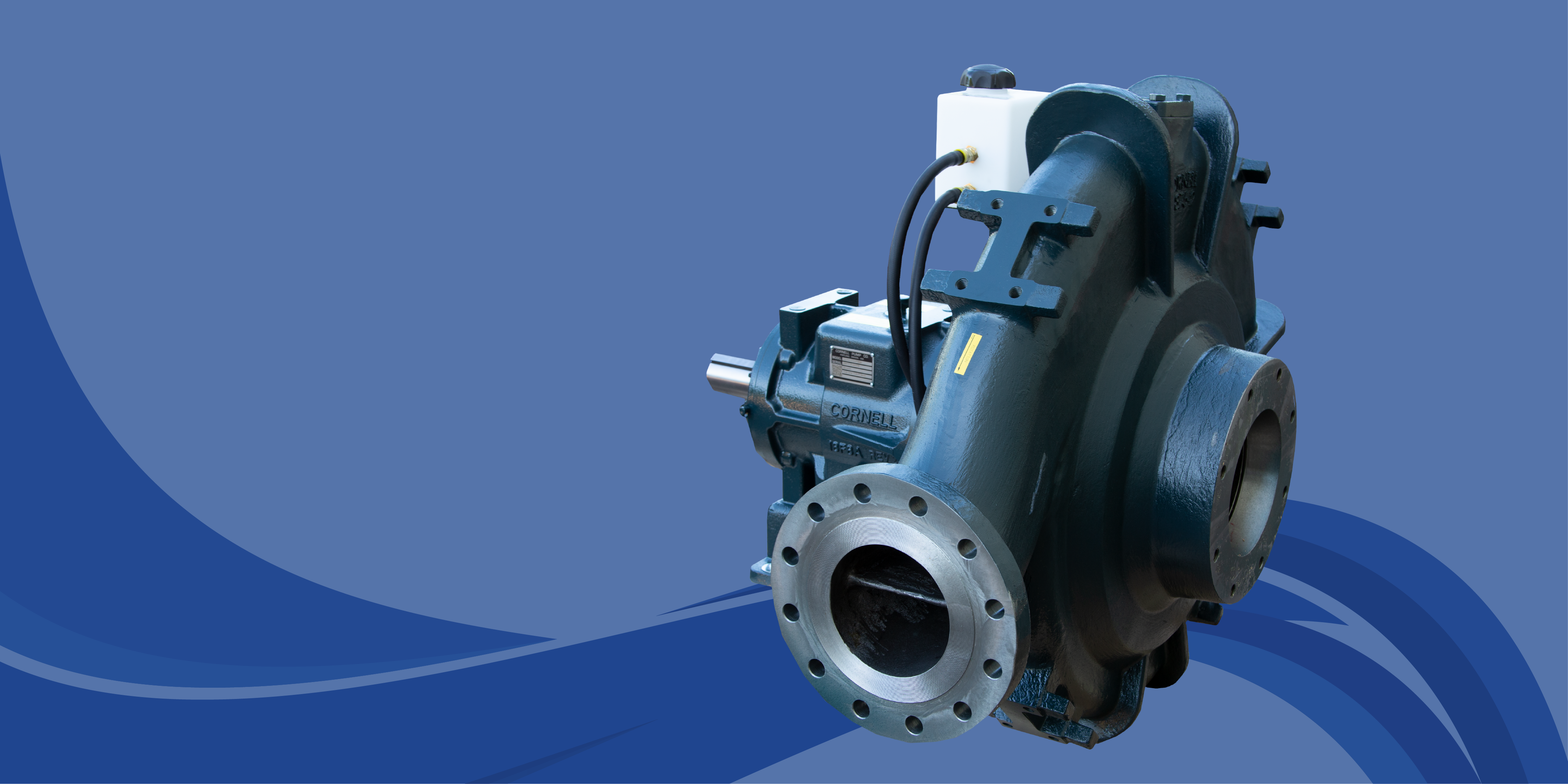

Hybrid Pumps

MX pumps are ideal for high-head mining, agriculture, and industry applications due to their long service life and suction lift capabilities. They have multi-vane, enclosed impellers designed for industry-leading efficiency and are available in the horizontal frame and SAE engine-mounted configurations.

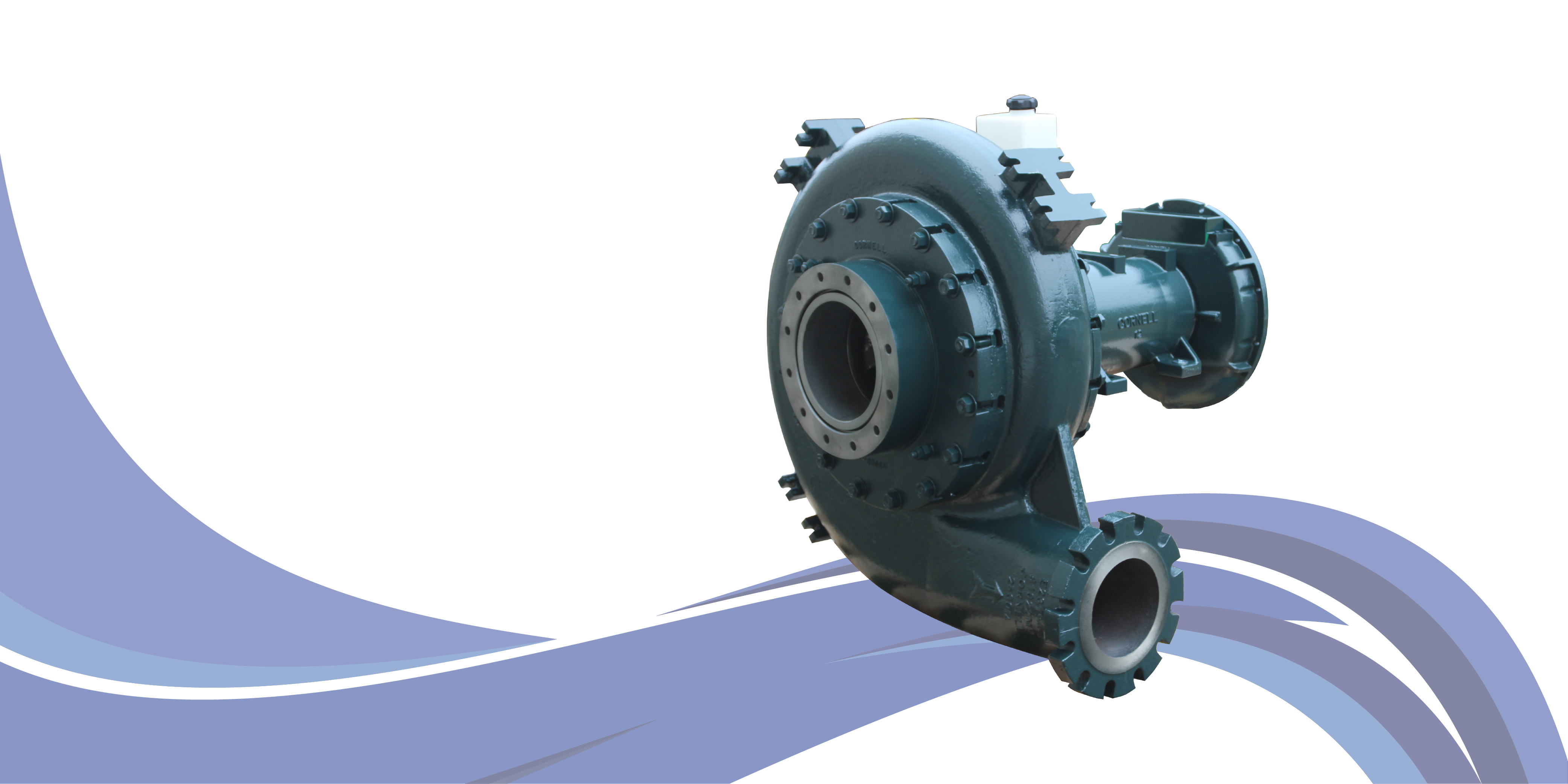

MP Series Pumps

The MP-Series Pumps from Cornell are built to handle coarse abrasives and provide reliable service in slurry pumping. With over 70 years of pump design and manufacturing expertise, Cornell has developed the patented Cycloseal® technology to enhance the MP Mining Pump Series. These pumps are engineered for high operating pressures and can handle demanding abrasive slurry applications such as coal, sand, gravel, manure, and mine dewatering. The MP pumps feature oversized shafts, thick volutes, and high-chrome white iron impellers, delivering more extended service life in harsh conditions than standard slurry pumps. Look for the distinctive pushed-out rectangular design of the Cornell frame to identify a quality Cornell pump.

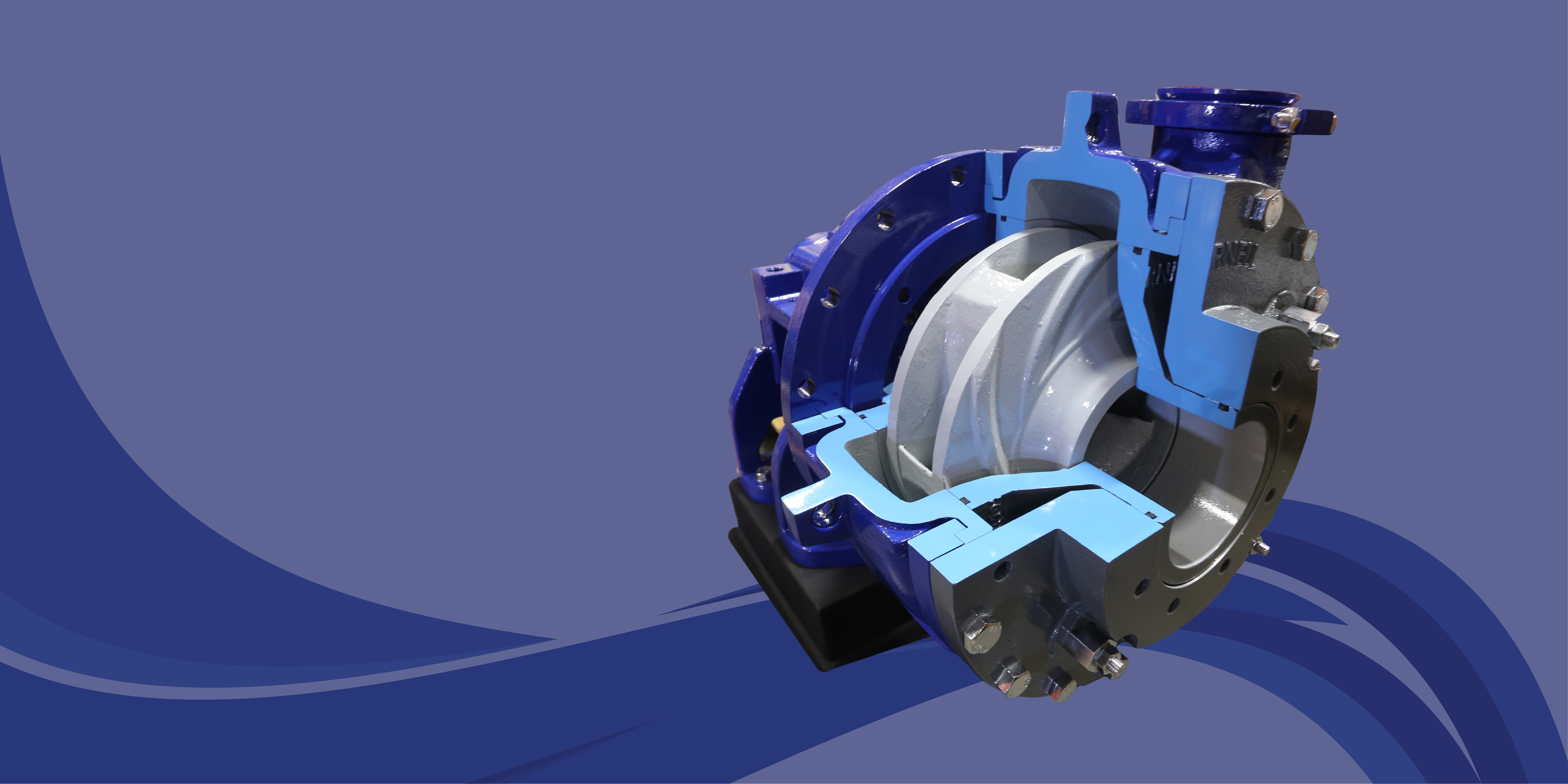

SP Series Pumps

Cornell's SP Series Slurry pump is designed for mining applications and incorporates patented Cycloseal® technology. With its ability to handle abrasive materials in the mill process, the SP Series is a valuable addition to Cornell's range of mine dewatering pumps. The pump has rubber and metal-lined configurations to accommodate different particle sizes and pH requirements.

SM Series Pumps

The SM series pumps are hard metal and designed for high head and multistage slurry pumping applications with a standard pressure rating of 600 PSI. All wet-end components are made of high chrome white iron alloy. The SM pump features a unique adjustable suction wear plate with the patented Cycloguard feature to minimize recirculation and extend wear life. The angular, muscular frame of the SM pump is easily recognizable as a quality Cornell pump.

Self-Priming Pumps

Cornell's self-priming pumps are highly efficient and renowned in the industry for their durability, power, and energy efficiency. Their patented-Cycloseal® back plate technology makes them even more durable. These pumps, including the STX, STH, and STL series, are easy to maintain and perfect for wastewater, slurry, and water transfer applications.