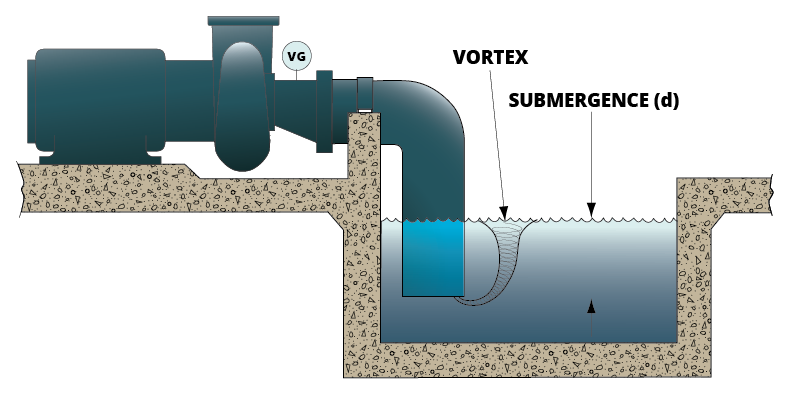

If a pump suction is not placed an acceptable distance from the surface of the liquid, the pump can experience vortexing. Similar to cavitation, with the loss of efficiency and damage that can occur to the pump, vortexing is the result of too much water relative to the pit/sump depth being drawn into the suction line. A depression forms on the surface of the water and is commonly seen as a whirling vortex.

Many have seen a whirling vortex form when a sink or bathtub drains. As the water level in the tub decreases, the ferocity of the whirlpool increases, with a column of air often visible all the way into the drain. A noticeable whirl on the surface of the body of liquid being pumped does not need to be perceptible to human eyes to cause damage, and in the worst cases, a column of air can lead straight into the suction pipe.

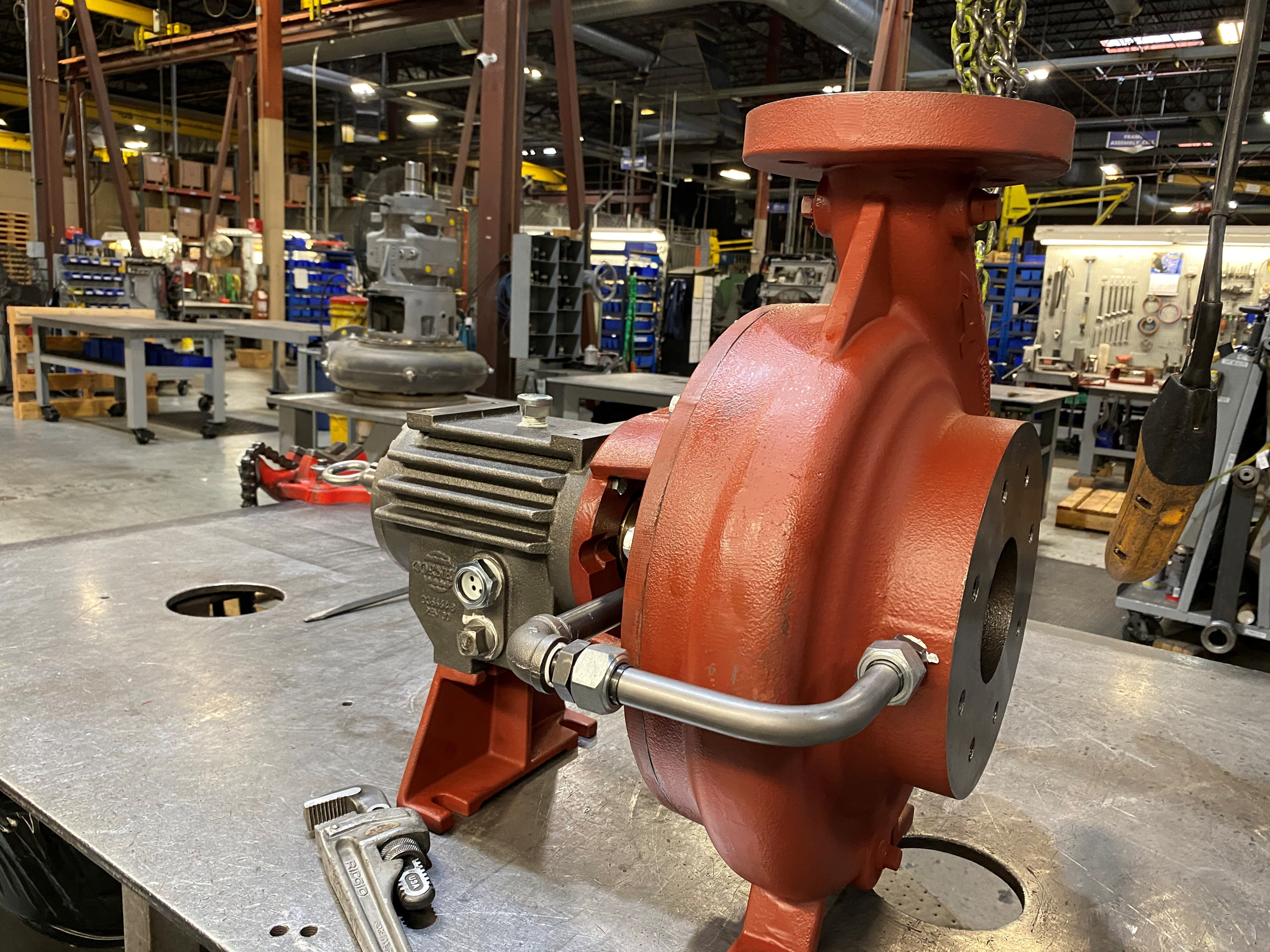

Vortexes form between the pump suction and intake tank fluid surface. This causes air to enter the pump suction, and the entrained air reduces pump capacity and efficiency. Excessive shaft deflection is also produced by the entrainment. The pump’s mechanical seals, bearings, piping, couplings and impeller can be damaged by the vortex condition.

Ideally, vortexing can be anticipated in the design phase and eliminated with the proper amount of suction for the water level. However, if a pump experiences vortexing, the issue can be reduced or stopped by changing the velocity of the water entering the pump. Reducing or eliminating vortexing can be accomplished through:

- Increasing the size of the inlet piping or installing a flared suction line

- Increasing the depth of the fluid source (or raising the pump to increase the distance between the bottom of the fluid source and the intake)

- Reducing the pump flow rate

- Operating at a different level to reduce head

- Slowing the system Reducing the number of pumps running in the fluid source

- Using diffuser screens or baffles

- Alerting the fluids/solids ratio in the intake

- Realigning the return line to reduce a waterfall effect in the liquid source

- Floating large balls on the surface to dissuade vortex formation

- Cleaning the trash screen to remove restrictions