Pumpline Blog

Stay up-to-date with the latest from Cornell.

Celebrate National French Fry Day — July 13

Where Every Golden Fry Meets Cornell engineering.

Read MoreCutters vs. Choppers: Choosing the Right Impeller for Modern Wastewater Challenges

As wastewater compositions evolve—with flushable wipes, fibrous materials, and grease-laden...

Read MoreThe Crucial Role of Metallurgy in Mining: Combatting Wear and Corrosion

In the world of mining, few factors impact equipment performance...

Read MoreSolving the Most Common Refrigeration Pump Issues: A Cornell Troubleshooting Guide

Practical Solutions for Liquid Overfeed and Transfer Pump Applications

Read MoreThe RPM2™ Seeker Provides Satellite Tracking for Critical Assets

In industries like construction, mining, oil and gas, and agriculture,...

Read MoreCornell Pump Holiday Closure – Independence Day

In observance of Independence Day, Cornell Pump will be closed...

Read MoreIntroducing the FlexiBase™: Faster Installs, Smarter Support for Agricultural Pumps

When it comes to agricultural pumping systems, speed and ease...

Read MoreTuesday Tip: Good Discharge Piping Makes a Big Difference

Recently, we shared best practices for suction piping. This week,...

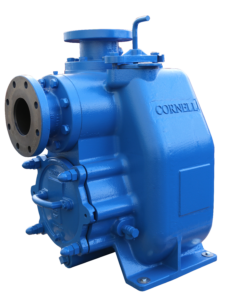

Read MoreCornell STX Self-Priming Pumps—Truly Efficient by Design

When selecting a self-priming pump, it’s easy to focus on...

Read MoreKEEP UP WITH THE LATEST NEWS

Subscribe today to keep up with all of Cornell Pump's news.