Pumpline Blog

Stay up-to-date with the latest from Cornell.

Explore Cornell Pump’s YouTube Channel for How-To Guidance and More

Cornell Pump’s YouTube channel is your go-to resource for in-depth...

Read MoreImportance of Using Parts Kits for Pump Maintenance and Repair

When it comes to pump maintenance, speed, accuracy, and reliability...

Read MoreCelebrate National French Fry Day — July 13

Where Every Golden Fry Meets Cornell engineering.

Read MoreCutters vs. Choppers: Choosing the Right Impeller for Modern Wastewater Challenges

As wastewater compositions evolve—with flushable wipes, fibrous materials, and grease-laden...

Read MoreThe Crucial Role of Metallurgy in Mining: Combatting Wear and Corrosion

In the world of mining, few factors impact equipment performance...

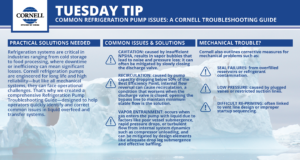

Read MoreSolving the Most Common Refrigeration Pump Issues: A Cornell Troubleshooting Guide

Practical Solutions for Liquid Overfeed and Transfer Pump Applications

Read MoreThe RPM2™ Seeker Provides Satellite Tracking for Critical Assets

In industries like construction, mining, oil and gas, and agriculture,...

Read MoreCornell Pump Holiday Closure – Independence Day

In observance of Independence Day, Cornell Pump will be closed...

Read MoreIntroducing the FlexiBase™: Faster Installs, Smarter Support for Agricultural Pumps

When it comes to agricultural pumping systems, speed and ease...

Read MoreKEEP UP WITH THE LATEST NEWS

Subscribe today to keep up with all of Cornell Pump's news.