Preventing Cavitation in Agricultural Pumps

Agricultural pumping applications often operate with long suction runs, fluctuating water levels, and debris-laden sources such as ponds, canals, and reservoirs. These conditions make cavitation one of the most common performance problems in the field. Cavitation reduces flow, erodes impellers, increases vibration, and shortens pump life.

Using Cornell Pump RunDry® to Prevent Seal Damage

Running a centrifugal pump without liquid is one of the fastest ways to damage mechanical seals. Even a brief run-dry event can overheat the seal faces, crack elastomers, and dramatically shorten pump life. Cornell Pump developed the RunDry® system to address this problem directly, giving operators a reliable method to protect seals during low flow or no flow conditions.

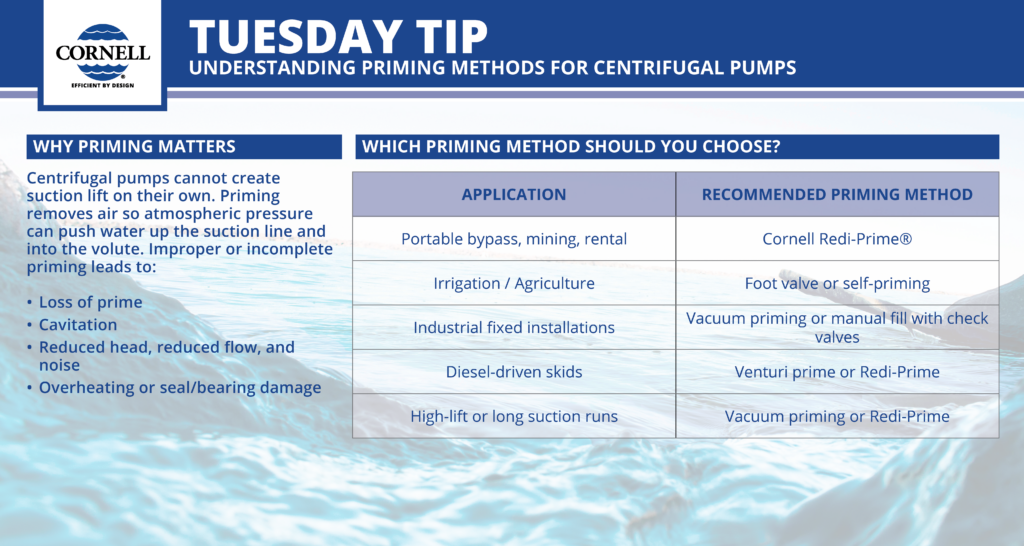

Tuesday Tip: Understanding Priming Methods for Centrifugal Pumps

Before a centrifugal pump can move liquid, its casing and suction line must be filled with fluid. Air is the enemy of pump performance—just 3% entrained air can cause a centrifugal pump to lose prime.

Cornell pumps can be primed in several ways depending on installation, duty cycle, and automation needs. Here is a clear overview of common priming methods—how they work, and their advantages and disadvantages.

How Industrial Pumps Support Critical Manufacturing Processes

In every major manufacturing sector—from food processing and chemical production to mining, pulp and paper, and general industry—industrial pumps are the hidden workhorses that keep processes running smoothly. They move raw materials, manage waste streams, regulate heat transfer, and maintain pressure in systems that must operate with precision and reliability. Without pumps, production lines would stop, safety systems would fail, and efficiency would collapse.

Diesel Skids vs. Electric Packages: Choosing the Right Power for Your Pump System

When designing or specifying a pump package, one of the most important early decisions is the power source. Cornell Pump offers both diesel-driven skid packages and electric-motor packages—each designed for reliability, efficiency, and ease of installation. But their advantages differ depending on your site conditions, mobility needs, and cost priorities.

Throwback Thursday – The Cornell Advantage, 1950s Style

We’re stepping back in time to the 1950s, when Cornell Pumps was already leading the way in reliability and innovation. This lighthearted brochure, filled with hand-drawn illustrations and bold red lettering, highlighted the qualities that defined Cornell then and still define us today.

Unlocking Efficiency: How to Use the Cornell Pump eCatalog

In today’s fast-paced pump specification environment, access to real-time product information and configurable solutions is key. That’s where the Cornell Pump eCatalog comes in — a powerful, user-friendly online platform giving engineers, specifiers, distributors and end-users direct access to Cornell’s full pump portfolio.

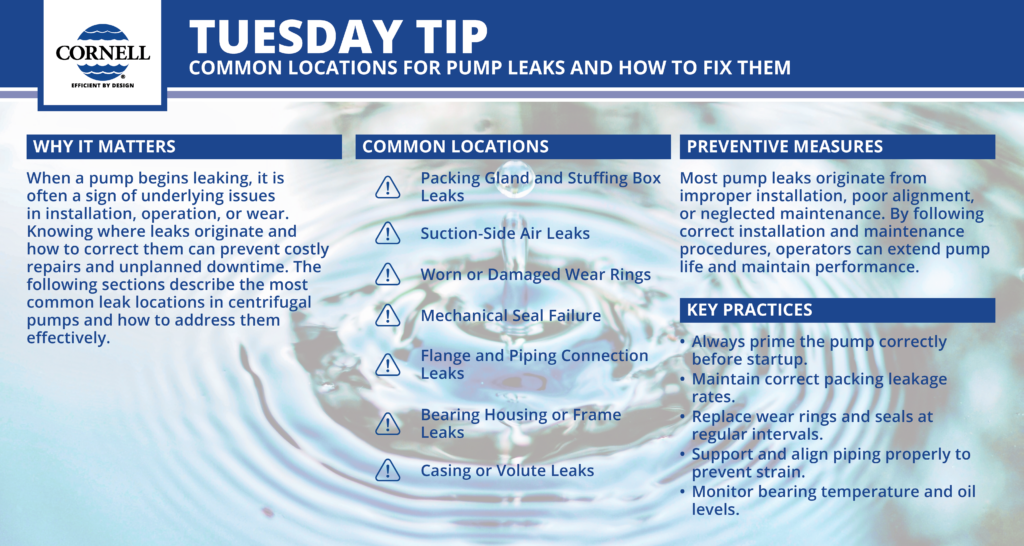

Tuesday tip: Common Locations for Pump Leaks and How to Fix Them

When a pump begins leaking, it is often a sign of underlying issues in installation, operation, or wear. Knowing where leaks originate and how to correct them can prevent costly repairs and unplanned downtime. The following sections describe the most common leak locations in centrifugal pumps and how to address them effectively.

Cornell’s Cycloseal® Pumps Prove Their Worth in Colombian Nickel Mining

Cornell Pump’s patented Cycloseal® technology is redefining pump reliability in mining. Learn how a Colombian nickel mine achieved over 9,000 hours of flawless operation, zero downtime, and massive cost savings using Cornell’s mining pumps.

Cornell Co-Pilot™ External Vibration Sensor: Smart Monitoring for Smarter Pump Performance

Cornell Pump Company continues its tradition of innovation with the Co-Pilot™ External Vibration Sensor (EVS)—a rugged, intelligent, and highly adaptable device that helps operators monitor the health of pumps, motors, and other rotating equipment in real time. Designed for reliability and ease of integration, the EVS provides actionable insights that can prevent costly downtime and extend equipment life.