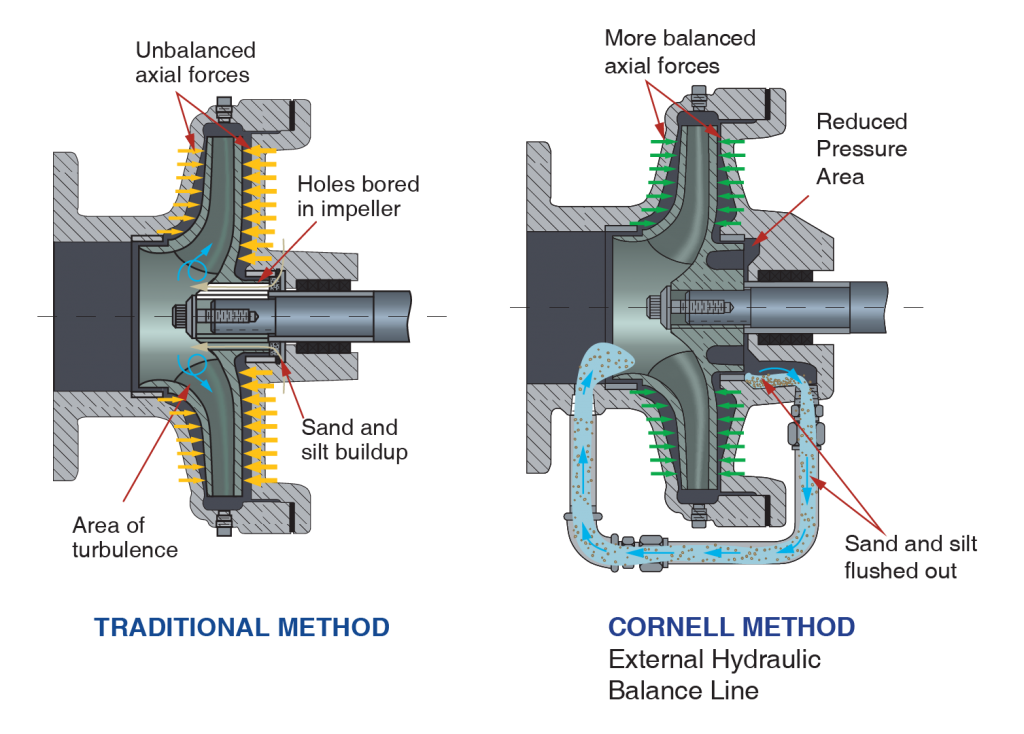

A feature on many Cornell clear liquid pumps, an external hydraulic balance line, allows better performance, without having to drill holes in impellers. The following copy comes from Cornell Pump’s Hydraulic Seminar Workbook—lasted updated in 2019.

THE EXTERNAL HYDRAULIC BALANCE LINE

To lower pressure in the stuffing box (or seal chamber) and to attempt to limit the inherent axial force created by the impeller, traditional centrifugal pump designs use large holes bored through the impeller. Cornell has a more effective method –THE EXTERNAL HYDRAULIC BALANCE LINE.

High pressure liquid from the volute passes through the hub ring clearances into the cavity between the stuffing box and the impeller. Liquid returns via the balance line to the region of lower pressure at the pump inlet, taking with it any sand or silt that may otherwise build up at the stuffing box. This method reduces turbulence, improves hydraulic efficiency, increases the life of packing, mechanical seals, and bearings – provides positive control of axial forces. It also reduces wear because sand is not trapped behind the impeller, near the shaft.