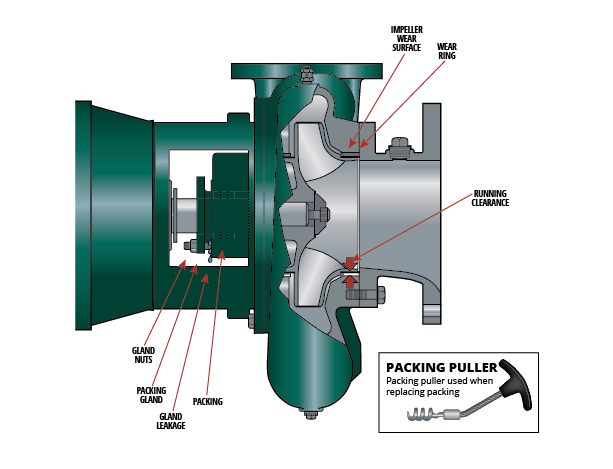

Packing is often used as a sealing method for general purpose and agricultural pumps. For the packing to be effective, and not be overheated by the shaft rotation, there must be a consistent drip of liquid, about one drip per second.

Running clearance on most new general purpose water pumps is about .010 inch on a side. (check with the factory for specifications on for your model). If wear increases this to .032 inch, the wear ring should be replaced and the impeller repaired or replaced. Wear may be caused by abrasives in the pumpage, unsupported piping loads, or other causes.

Tighten the gland nuts 1/4 turn every ten minutes until a leakage of only 40–60 drops per minutes is achieved. If the packing must be replaced, a packing puller may be needed.

The diagram is from Cornell Pump’s Installation and Care book; a workbook that provides great ideas and reminders for pump set-up and operation. Every registrant to our Virtual Pump School will not only get this workbook, but also our Pump Seminar workbook and Condensed Hydraulic Data Book, along with (most importantly) more than 15 hours of pump and hydraulic instruction. Learn more about Virtual Pump School.