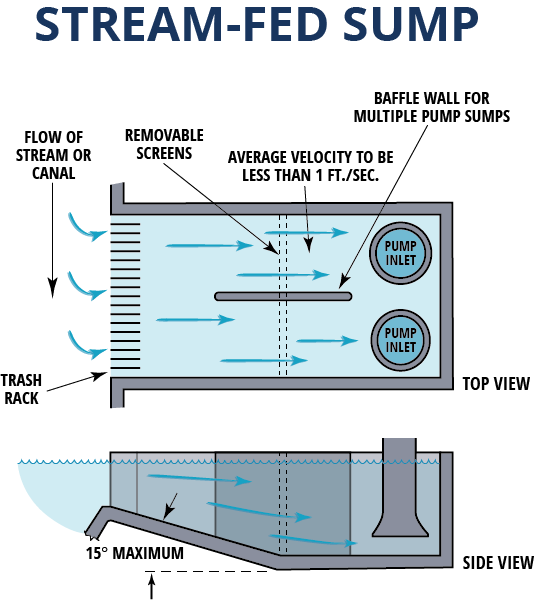

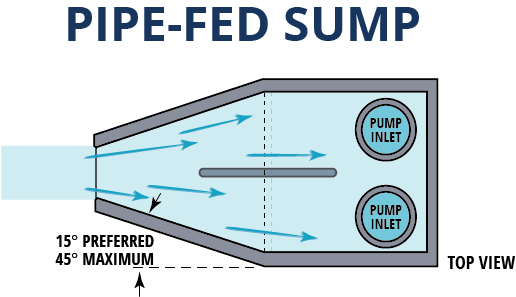

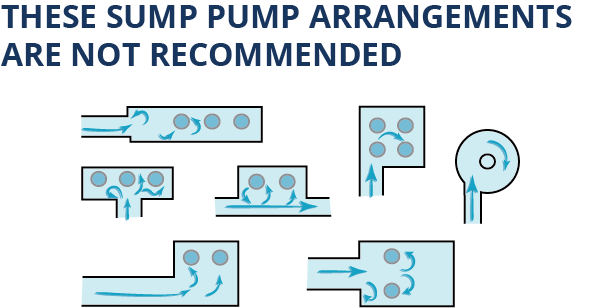

Proper sump design on wet wells and collection ponds help avoid air entrainment in pumps. That air entrainment can lead to cavitation, loss of efficiency, increased maintenance, and shorter pump life.

Below are some suggestions to better design sumps to avoid problems.